Bulk precision CNC lathe work services for high and low volume machined parts. Works with aluminum, brass, copper, carbon steel, leaded steel, stainless steel, plastic, Hastelloy® and Inconel®. Capable of turning parts from 0.030 to 2 in. OD. Other capabilities include multi-spindle machining, CNC vertical milling and wire cutting. Additional services such as cutting off and end working for facing, ID/OD chamfering, threading, tapping, centering, drilling, marking, reaming and tapering offered. Suitable for rubber bonded to metal and plastic industries, appliance and automotive manufacturers and assorted OEM businesses. 24/7 services available. ITAR registered. JCP compliant. On-time delivery. Made in the USA.

We can provide Cnc Turning Tool Bar, Mini CNC turning Machin, Stainless Steel Precis Cnc Turning Parts, etc.

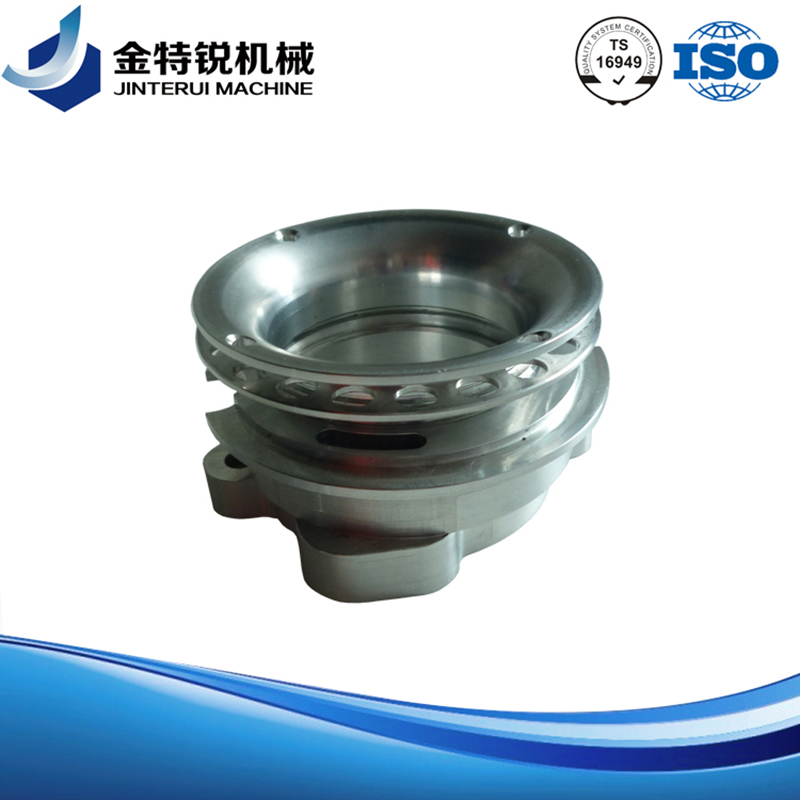

Products Name: CNC turning precision mechanical plastic parts Type:CNC Turning Application areas: Automotive, Automation, Test systems, Sensors, Medical, Sports, Consumer, Home appliance, Electronic, Pumps, Computers, Power and energy, Architecture, Printing, Food, Textile machinery, Optical, Lighting, Security and safety, AOI, SMT equipment, etc Material Aluminum: 5052, 6061,6063, 2017, 7075, etc Stainless Steel Alloy: 303, 304, 316, 412, etc Steel Alloy: Carbon Steel, Die Steel, Spring Steel, Cold Rolled Steel etc Brass Alloy: 3602, 2604, H59, H62, etc. Other Special Materials: Copper, Plastics, Lucite, Nylon, Bakelite, Carbon, PP, PC, PE, PEEK, Titanium etc Surface Finishing: Anodizing, Bead Blasting, Hard Coat Anodizing, Heat-treating, Induction Heat Treating, Laser Etching, Pad Printing, Painting,Parkerizing, Plating, Polishing. Powder Coating, Precious Metal Plating Process Drawing&Samples-Mould making-Die casting-Deburring-Drilling and threading- CNC Machining-Polshing-Surface treatment-Assembly-Quality inspection-Packing-Shipping Tolerance: According to drawings. Equipment: Vertical Machining Center, Vertical Drilling Center, 4-Axis Machining Center, Turning Machine, Drilling Machine, Sawing Machine, Hydraulic Press, Air Leak Tester, CMM Preferred formats:JPEG, PDF, PNG, CAD, IGS, UG, Solidworks Loading port: Chongqing Delivery time: 20-30 days after receiving orders,usually based on customers' PO QTY Note: Above item is only for your reference,not for sales;we only produce parts based on customer's drawings CHONGQING JIN TE RUI MACHINE Co.,ltd is a professional manufacturer dedicated to the design and development of aluminum alloy parts Rapid Prototyping, aluminum alloy calendering and precision machining, as well as new products. Adhering to the "integrity-based, continuous innovation, the Pursuit of excellence" business philosophy, with a wealth of experience determined to provide customers with excellent products to return customers, the development of enterprises can not be separated from your support, CHONGQING JIN TE Rui sincerely hope to work with new and old friends to create brilliant. product pictures 1.Customize products according to customers` requirement. 2. First-rate machining equipment,ensure the quality of each process. 3. Low(1-2%)scrap rate 100% inspection(offer QC report). 4. Direct from factory.

The long-term provision of quality services is our commitment! We look forward to cooperating with you. We will dedicated serve for you at any time if you need!

Product Categories : CNC Machining > CNC Turn-mill