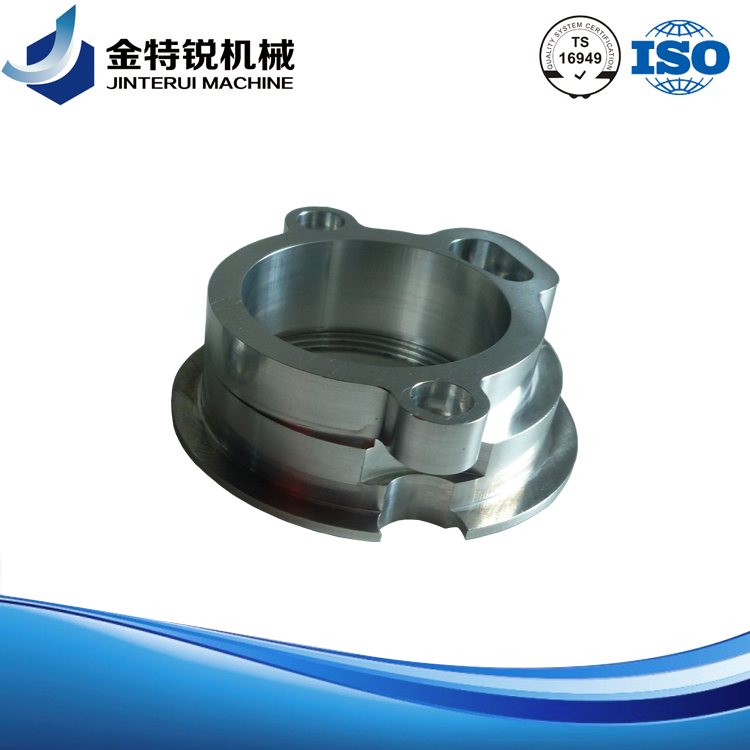

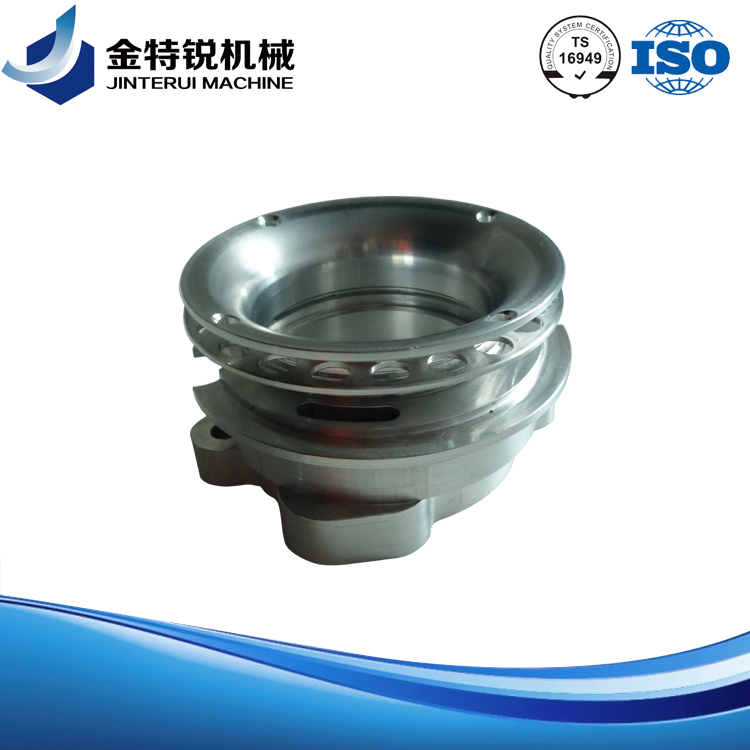

Model No.: JTR-3116

Brand: JTR/OEM

Packaging: Export carton, wooden case, pallet or according to your requst

Productivity: 30000

Transportation: Ocean,Land,Air

Place of Origin: ChongQing

Supply Ability: 10000/week

Certificate: IATS16949

Port: Chongqing

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CIF,EXW

Cnc Turning services for metals up to 8 in. with 0.0005 in. tolerance. Materials include steel, plastic, aluminum, brass & stainless steel. Capabilities include CNC milling, screw machining, precision saw cutting, Metal Stamping, broaching & assembly. Heat treating including quenching, case hardening, carburizing & stress relieving services are also available. Industries served include heavy, landscaping & lawn equipment, automotive, medical, tractor & outdoor recreation. On-time delivery.

We can provide CNC turning Tool Accessori, Cnc Turning Plastic,Micro Cnc Turning Machin, etc.

Product Categories : CNC Machining > CNC Turn-mill