Model No.: JTR-6887

Brand: JTR/OEM

Application: Machinery Accessory

Standard: ASME

Surface Treatment: Electroplating

Production Type: Batch Production

Machining Method: CNC Turning

Material: Nylon

Packaging: Export carton, wooden case, pallet or according to your requst

Productivity: 30000

Transportation: Ocean,Land,Air

Place of Origin: ChongQing

Supply Ability: 10000/week

Certificate: IATS16949

Port: Chongqing

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CIF,EXW

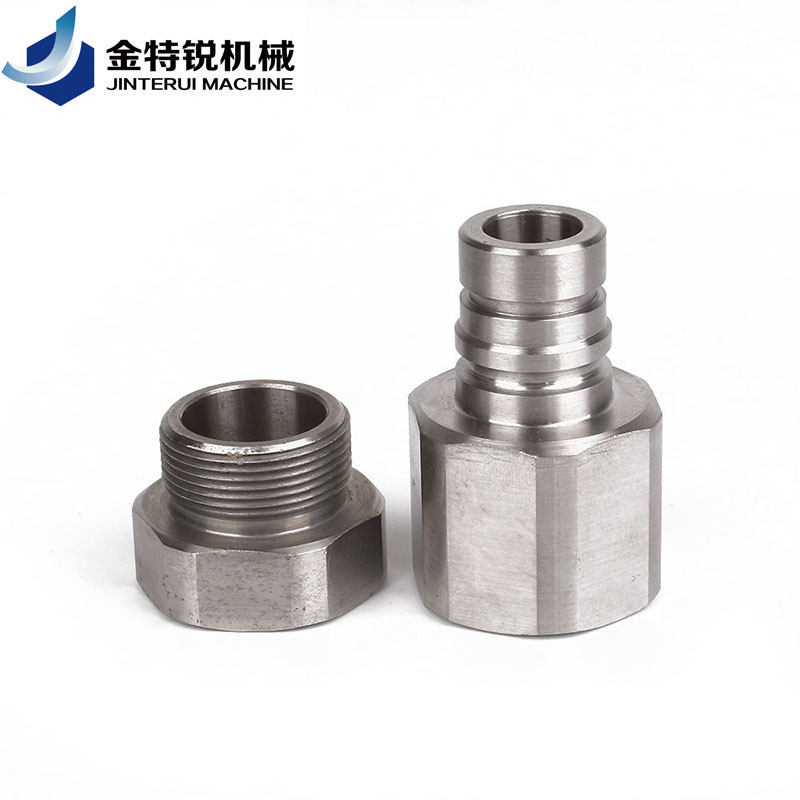

Products Name: Precision machining custom Aluminium Cnc Machining parts

AS9100c and ISO 9001:2008 manufacturer of turned parts. 4 inch diameter through the spindle, and capable of machining parts from .375 inches to 15 inches in diameter. Screw machine parts built to print, with materials including aluminum, steel & stainless steel and others. Industries served include aerospace, aircraft, medical, transportation, and military in both large and short runs. Also available are other secondary operations, and precision component contract manufacturing with quality control SPC and JIT delivery and lean manufacturing.

We can provide cnc wood turning machine in bangalore, lathe Cnc Turning center and mini CNC turning center.

Type:CNC Turning

Application areas: Manufacturing industry, information industry, medical equipment industry, military equipment, other industries Our clients

Our products have been sold to more than 100 countries in the past 10 years.We have huge customer resources that is long-term Relations of cooperation.

We are looking forward to cooperate with you. Welcome to or contact

Product Categories : CNC Machining > Cnc Turning