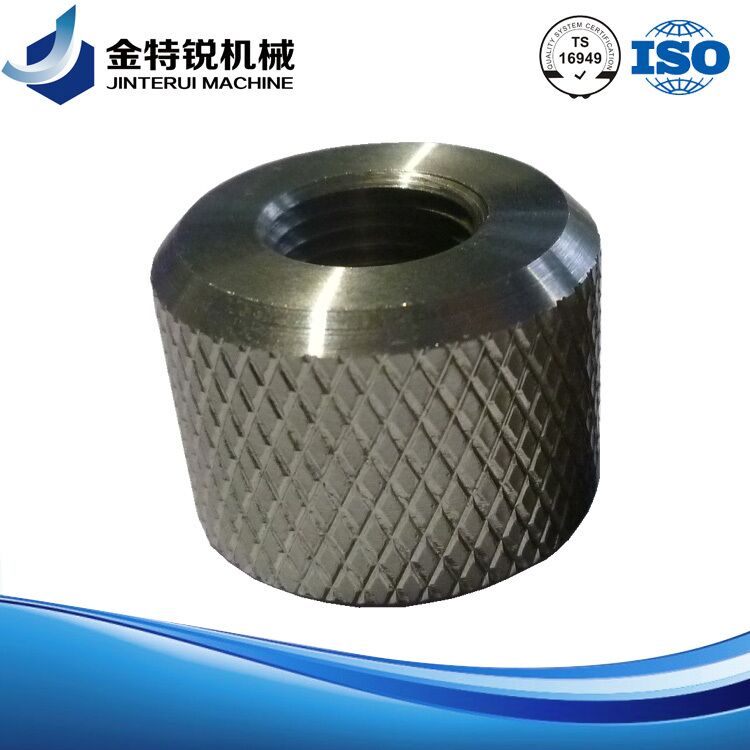

Model No.: JTR-0144

Brand: JTR/OEM

Application: Machinery Accessory

Standard: ASME

Surface Treatment: Electroplating

Production Type: Batch Production

Machining Method: CNC Turning

Material: Nylon

Packaging: Export carton, wooden case, pallet or according to your requst

Productivity: 30000

Transportation: Ocean,Land,Air

Place of Origin: ChongQing

Supply Ability: 10000/week

Certificate: IATS16949

Port: Chongqing

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CIF,EXW

Precision Cnc Turning services for components and parts. Capable of turning parts with up to 13 in. diameter sizes. Available from prototypes to high-volume production runs. Materials worked with include aluminum, stainless steel, titanium, copper, magnesium, molybdenum, ferrous and non-ferrous steels, high-tech plastics, nickel and high nickel alloys, and castings and forgings. Industries served include aerospace, research, medical, defense, automotive, and molding. CAD design, tooling design, assembly, and surface grinding services are provided.We can provide Basebal Bat Cnc Wood Turning Lathe, Cnc Lathe Turning Parts Machining, Cnc Tool Holder CNC turning Tool, etc.

Fashion design and high quality is your best choice. We look forward to cooperating with you.

Product Categories : CNC Machining > Cnc Turning