Model No.: JTR-1254

Brand: JTR/OEM

Application: Hardware Tool

Standard: ASME

Surface Treatment: Polishing

Production Type: Batch Production

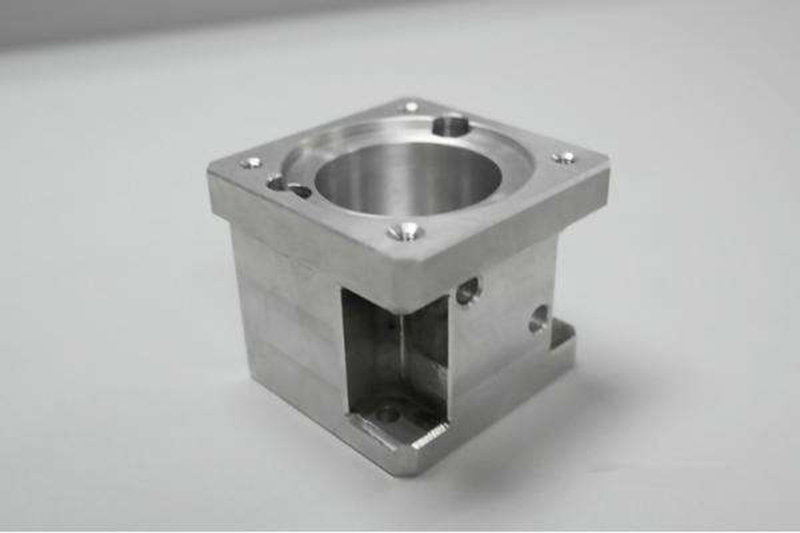

Machining Method: CNC Milling

Material: Aluminum

Packaging: Export carton, wooden case, pallet or according to your requst

Productivity: 30000

Transportation: Ocean,Land,Air

Place of Origin: ChongQing

Supply Ability: 10000/week

Certificate: IATS16949

Port: Chongqing

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CIF,EXW

Products Name: CNC millinsg anodized machining components

JTR Company has a strong equipment strength and testing equipment strength, only for the determination to provide quality products have been back to customers.

JTR machine is a professional factory of custom CNC milling steel parts. Our steel machined parts ranges froom SS316 steel milled parts, CNC SS304 parts etc.

We can provide Cnc Lathe Milling Machine, Mould Cnc Milling Machine, 5 Axis Cnc Machine Milling, etc.

Type:CNC Milling, Precision Nonstandard Parts(OEM Service)

Main Material: Aluminium AlloyOur services

We provide OEM or ODM service for customers.

We provide one-stop service of customized aluminum alloy casting products

We can help clients design drawings and solve complex problems.

To protect your 3d files and other informations,we have taken two methods.

1.We could sign NDA with you as you required.

2.All of the computers in our company have installed confidential software.Without the password,no one could get access to the files.

Product Categories : CNC Machining > Cnc Milling