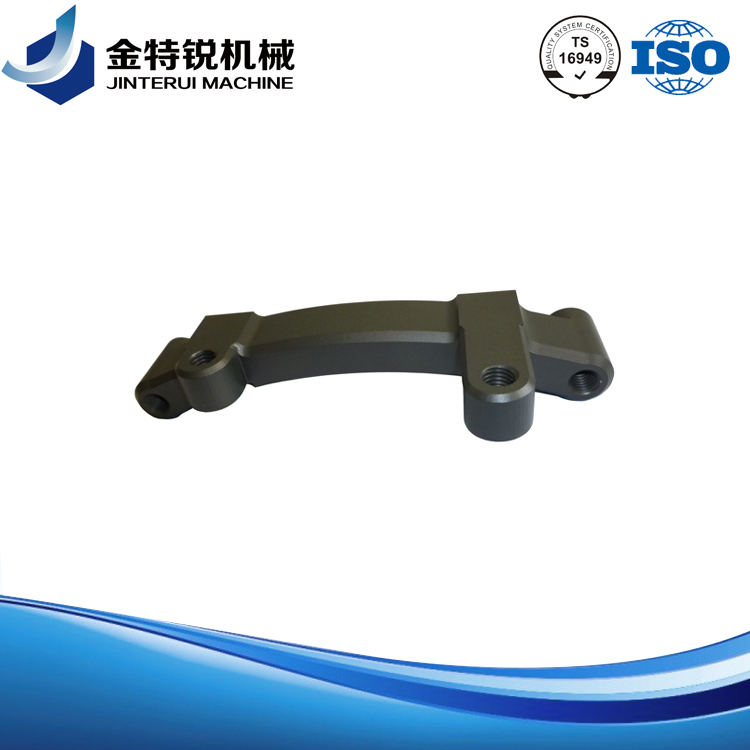

Model No.: JTR-2235

Brand: JTR/OEM

Application: Machinery Accessory

Standard: ASME

Surface Treatment: Polishing

Production Type: Batch Production

Machining Method: CNC Milling

Material: Aluminum

Packaging: Export carton, wooden case, pallet or according to your requst

Productivity: 30000

Transportation: Ocean,Land,Air

Place of Origin: ChongQing

Supply Ability: 10000/week

Certificate: IATS16949

Port: Chongqing

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CIF,EXW

Products Name: Aluminum Alloy Cnc Milling Parts

We can provide Aluminum Parts CNC milling, Cnc Milling Part, Cnc Milling Operation, ect.

Precision vertical milling for aerospace, agriculture, electronic, automotive, medical, military, telecommunication and various other applications. Aluminum, beryllium copper, brass, bronze, nickel, steel and stainless steel materials worked with. Other capabilities include punching, cutting, pressing, forming, welding and stamping. Prototype and short run production can be done. Finishing services include deburring, polishing, painting, plating, anodizing, silk screening, passivation and heat treating. On-time delivery.

Surface treatment: anodic oxidation

Type:CNC Milling

Scope of application: machine tools, automobiles, aircraft, etc

Company strength:

The company actively expand the business market, product tactile extension to the automotive, motorcycle, through-machine, communications and military industry, some products are exported to Southeast Asia and Europe and the European market.

At present, the company mainly serves the German BMW large displacement motorcycle, Ericsson Communications Base station, Chaoyang Heavy diesel engine, Zongshen Tong Machine, Changan automobile shares, Qingfeng automobile shares and other customers.

Equipment strength:

The company has more than 70 sets of various models of precision CNC processing equipment, equipped with three-axis, four-axis machining center, drilling Attack Center, CNC Lathe (Japan's five-axis dual-spindle milling composite, four-axis dual-spindle milling composite, four-axis double spindle walking heart, ordinary oblique bed body).

There are more than 10 lathes, milling machines, drilling machines, grinders and other ordinary machine tools, 2 500t-1000t precision cold chamber die-casting machine, all equipment annual processing capacity of up to millions.

Testing Equipment:

Division I has a high-precision Hexcon CMM Three coordinate detector, projector, roughness meter, contour meter, pneumatic gauge and other general precision measuring instruments and special inspection tools to ensure that products in the sample development, trial production and mass production at all stages to meet the different needs of customers.

Material

Aluminum: AL5052, AL6061, AL6063, AL2017, AL7075, etc

Stainless Steel Alloy: SS303, SS304, SS316, SS412, etc

Steel Alloy: Carbon Steel, Die Steel, Spring Steel, Cold Rolled Steel etc

Brass Alloy: 3602, 2604, H59, H62, etc.

Other Special Materials: Copper, Plastics, Lucite, Nylon, Bakelite, Carbon, PP, PC, PE, PEEK, Titanium etc

Surface Finishing: Anodizing, Bead Blasting, Hard Coat Anodizing, Heat-treating, Induction Heat Treating, Laser Etching, Pad Printing, Painting,Parkerizing, Plating, Polishing. Powder Coating, Precious Metal Plating

Process Drawing&Samples-Mould making-Die casting-Deburring-Drilling and threading- CNC Machining-Polshing-Surface treatment-Assembly-Quality inspection-Packing-Shipping

Tolerance: According to drawings.

Equipment: Vertical Machining Center, Vertical Drilling Center, 4-Axis Machining Center, Turning Machine, Drilling Machine, Sawing Machine, Hydraulic Press, Air Leak Tester, CMM

Preferred formats:JPEG, PDF, PNG, CAD, IGS, UG, Solidworks

Loading port: Chongqing

Delivery time: 20-30 days after receiving orders,usually based on customers' PO QTY

Note: Above item is only for your reference,not for sales;we only produce parts based on customer's drawings

1. Design

At our enterprise ,we have many experts that can help with the design process. We are able to help you create drawings, reverse engineer parts, and do 3D/CAD drawings.

2. Die Casting

JTR has a partner die casting factory to get your castings done efficiently for both small lot or large capacity jobs.

3. JTR owns more than thirty CNC Machines including 8 sets 4-Axis Cnc Machining center and 6 years experience in metal machining to develop and process you parts.

4. Finishing

JTR knows that a part is not complete without finishing.We work with qualified finishing suppliers to get your product finished hassle-free.

Product Categories : CNC Machining > Cnc Milling