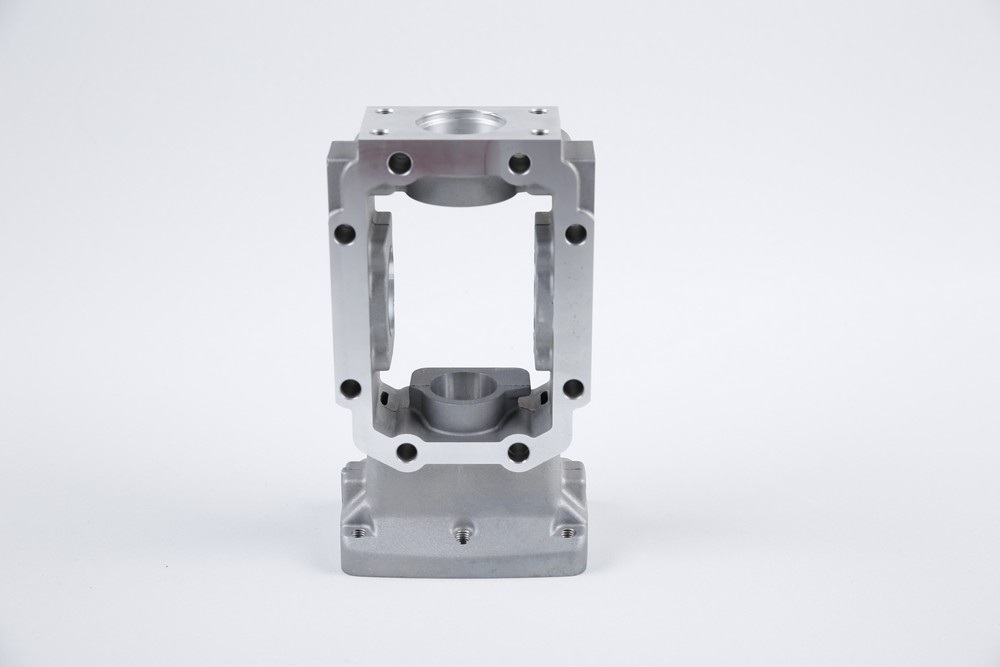

Model No.: JTR-5117

Brand: JTR/OEM

Die Casting Machine Type: Hot Chamber Die Casting Machine

Die Casting Method: Precision Die Casting

Application: Machinery Parts

Machining: CNC Machining

Material: Aluminum

Surface Preparation: Polishing

Pressure Chamber Structure: Horizontal

Tolerance Grade: 4

Casting Surface Quality Level: 3

Certification: ISO 9001:2008

Packaging: Export carton, wooden case, pallet or according to your requst

Productivity: 30000

Transportation: Ocean,Land,Air

Place of Origin: ChongQing

Supply Ability: 10000/week

Certificate: IATS16949

Port: Chongqing

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,CIF,EXW

Products Name:Die casting aluminium auto parts casting

CHONGQING JIN TE RUI MACHINE Co.,ltd is a professional manufacturer dedicated to the Rapid Prototyping of aluminum alloy parts, precision machining, aluminum die-casting, sheet stamping pressure and new product design and development as one.

Product Categories : Die Casting > Aluminum Die Casting